9 Reasons Commercial Plastics Are Revolutionizing Manufacturing

In the world of manufacturing, innovation is key to staying ahead. One such innovation that has transformed the industry is the use of commercial plastics. Often seen as mere materials, commercial plastics are becoming game-changers in how products are designed, produced, and distributed. Here are nine compelling reasons why commercial plastics are revolutionizing manufacturing.

1. Enhanced Durability and Performance

Commercial plastics offer remarkable strength and resilience, making them ideal for various applications, from packaging to automotive parts. But what does this really mean for the industry? It means products can withstand harsh conditions and everyday wear and tear without compromising integrity. This durability translates to longer-lasting items that not only enhance consumer satisfaction but also reduce the need for frequent replacements, thereby promoting a more sustainable consumption pattern.

Moreover, the advanced technology behind commercial plastics allows manufacturers to engineer materials for specific performance criteria. Take, for example, the automotive sector; here, lighter and stronger plastics lead to improved fuel efficiency and reduced emissions. It's a win-win situation—enhanced performance meets environmental responsibility. In this way, the durability of commercial plastics extends far beyond their initial applications and impacts entire ecosystems.

2. Lightweight Solutions for Heavy Industries

The lightweight nature of commercial plastics helps to reduce transportation costs and energy consumption, leading to more sustainable manufacturing practices. When you consider the logistics involved in transporting heavy items, the differences become clear. With intentional use of plastics, companies can cut down on the weight of their products, thereby minimizing fuel consumption. Less fuel means lower emissions—not just an advantage for the bottom line but a victory for our planet.

In industries like aerospace and automotive, reducing weight can lead to incredible advancements. For instance, using commercial plastics in component manufacturing translates into significant weight savings that enhance fuel efficiency. This trend also allows companies to be more competitive by exploring the potential of lighter, more efficient designs. As the industry progresses, we'll likely see an even broader application of lightweight commercial plastics, reshaping the way we think about heavy industries.

3. Cost-Effective Production Methods

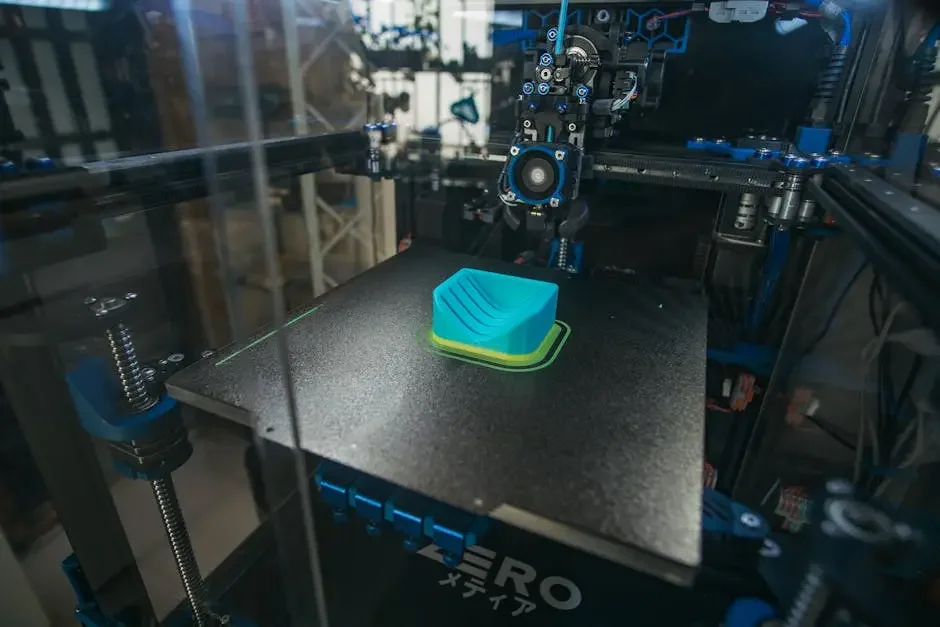

With their versatility and ability to be molded into complex shapes, commercial plastics can lower production costs significantly. By using injection molding and 3D printing techniques, manufacturers can now create intricate designs that would be unthinkable with traditional materials. This flexibility doesn't just simplify the creative process, it also streamlines production, allowing brands to scale up quickly without the usual growing pains.

In addition, the cost-effectiveness of commercial plastics enables smaller businesses to compete in markets historically dominated by larger firms. By leveraging these materials, startups can innovate and produce products that meet consumer demand without needing substantial investment. This democratization of manufacturing is exciting as it fosters a culture of creativity and entrepreneurship, ultimately leading to vibrancy in the market.

4. Endless Design Possibilities

The flexibility of commercial plastics encourages innovative design approaches, allowing manufacturers to push boundaries and create unique products. Imagine the designs that are possible when manufacturers can experiment with textures, colors, and forms without the constraints of rigid materials. The result? A product lineup that captivates consumers and stands out in crowded marketplaces. Designers can dream bigger, and even complex shapes can become reality.

Moreover, this design potential isn’t limited to aesthetics alone. Practical designs that enhance functionality are becoming increasingly common. For example, incorporating textured finishes for better grip, or integrating features directly into the plastic during manufacturing, reduces the need for additional assembly. With endless possibilities in design, commercial plastics not only fuel creativity but also improve user experience.

5. Sustainability Through Recycling

Many commercial plastics are recyclable, enabling manufacturers to contribute to environmental sustainability and reduce waste. Modern recycling technologies allow plastics to be repurposed into high-quality materials, giving a second life to products that might otherwise end up in landfills. This circular approach not only preserves natural resources but also enhances corporate responsibility, a key factor in today’s conscientious consumer market.

Companies are increasingly adopting closed-loop systems where recycled plastics are returned to their original manufacturing process. This not only reduces costs but also minimizes the impact on the environment. As more brands recognize the value in sustainability, we’ll likely see an even greater shift toward integrating recycled materials into mainstream manufacturing, shaping an industry that balances between innovation and ecology.

6. Rapid Prototyping and Production

With advancements in technology, commercial plastics allow for quick prototyping, helping businesses get their products to market faster. In an era where speed often translates to a competitive edge, being able to iterate quickly is invaluable. Designers can create prototypes in a matter of days instead of weeks—enabling a cycle of testing, feedback, and refinement that can take place in record time.

This capability not only accelerates the development timeline but also invites continual improvement, as adjustments can be made based on real-world feedback. Businesses that implement rapid prototyping using commercial plastics often find themselves at the forefront of innovation, responding to market needs swiftly while achieving high-quality results. The ability to adapt and evolve quickly is essential in today’s fast-paced manufacturing landscape.

7. Improved Safety Standards

Commercial plastics can be engineered to meet stringent safety standards, ensuring that products are safe for consumers. From food packaging to medical devices, safety is paramount. The materials used in these applications are often scrutinized for their invisibility in daily use, which underscores the importance of reliable performance without compromising health.

Furthermore, advancements in material science enable manufacturers to create plastics that not only meet but sometimes exceed safety standards. This proactive approach minimizes risks and builds trust between brands and consumers. By prioritizing safety through the use of commercial plastics, manufacturers can enhance their reputation and ensure a loyal customer base.

8. Resistance to Chemicals and Corrosion

Many commercial plastics are resistant to chemicals and corrosion, making them suitable for use in harsh manufacturing environments. This intrinsic property of commercial plastics ensures longevity and functionality even in extreme conditions, allowing businesses to maintain operational efficiency without compromising product quality.

In sectors such as pharmaceuticals and food production, this resistance is critical. Equipment and containers made from resistant commercial plastics reduce the risk of contamination and degradation, leading to safer and more reliable manufacturing processes. With expanding applications in demanding industries, these plastics are quickly becoming indispensable.

9. Facilitating Smart Manufacturing

Commercial plastics are increasingly integrated with smart technologies, enhancing automation and efficiency in the manufacturing process. Whether it's sensors embedded within products or smart packaging that interacts with consumers, the incorporation of technology into plastics opens doors to innovative manufacturing solutions.

This synergy between commercial plastics and smart technologies enables data collection and real-time monitoring, providing insights that can drive further improvements. As manufacturers embrace these technologies, we're likely to see dramatic changes in how production lines operate and how companies respond to trends and consumer demands—a clear win in the push toward smarter manufacturing.