How Can Design for Manufacturability (DFM) Improve Product Quality?

In today's competitive market, producing high-quality products efficiently is essential. Design for Manufacturability (DFM) is a set of principles aimed at simplifying the manufacturing process to improve the quality of the final product. In this blog, we will explore how implementing DFM can lead to superior product quality.

Understand DFM Basics

Start by grasping the fundamental principles of Design for Manufacturability. Knowing its goals and methodologies is the first step in leveraging it for quality improvement.

DFM promotes concepts that streamline production processes. This includes reducing the number of components and simplifying assembly. By understanding these basics, teams can align their design efforts with manufacturing capabilities.

Moreover, DFM emphasizes early collaboration between design and manufacturing teams. This ensures that both sides are aware of the practical implications of design decisions. Clarity at this stage lays the foundation for higher quality outcomes.

Analyze Current Design Processes

Examine your existing design processes to identify areas where manufacturability can be enhanced. This analysis is crucial for pinpointing inefficiencies that may affect product quality.

Using tools such as value stream mapping can help visualize where delays or unnecessary complexities occur. By bringing these inefficiencies to light, teams can make informed decisions about where to focus their DFM efforts.

Consider involving team members from different disciplines during this analysis. Engaging a diverse array of perspectives can lead to more comprehensive insights on potential improvements, resulting in a product that is easier to manufacture and of higher quality.

Incorporate Simplicity in Design

Simplicity in design often leads to fewer manufacturing defects and improved quality. Aim to reduce complexity while maintaining functionality.

By focusing on essential features, designers can create products that are not only easier to manufacture but also more reliable. When each component serves a clear purpose, the chances of errors during both production and use decrease significantly.

Additionally, a simpler design often results in shorter assembly times and lower manufacturing costs. Thus, adopting simplicity can benefit the company’s bottom line while simultaneously enhancing product quality and user experience.

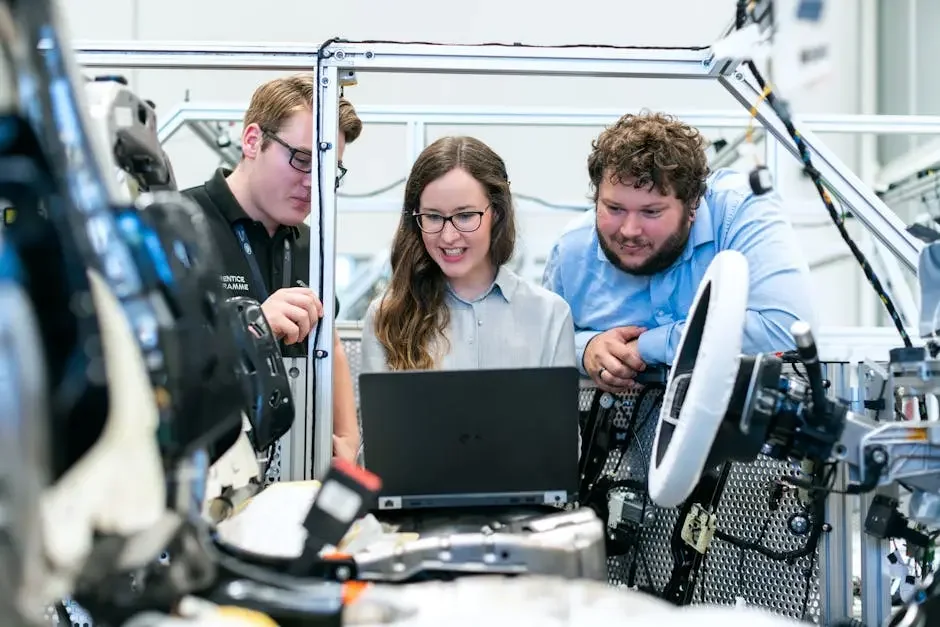

Engage Cross-Functional Teams

Involve teams from engineering, manufacturing, and quality assurance in the design process. Their insights are invaluable for enhancing product quality through DFM.

Cross-functional collaboration fosters innovation and helps uncover potential production issues before they arise. By discussing possible manufacturing challenges during the early design phase, teams can devise solutions proactively—saving time and resources later.

Moreover, different team members bring unique expertise, which can shed light on critical considerations. For instance, manufacturing engineers might have insights on materials that reduce costs while maintaining quality standards, leading to better DFM outcomes.

Conduct Rigorous Testing and Feedback

Implement thorough testing of prototypes to gather feedback on manufacturability and quality issues. This iterative process can lead to significant improvements.

Testing should not only focus on the product's functionality but also on how it can be manufactured. By receiving feedback from production teams during testing phases, designers can refine processes and avoid future quality issues.

Furthermore, gathering customer feedback post-launch can offer deep insights into how the product performs in real-world scenarios. This information feeds back into the design process, creating a continuous loop of improvement for future iterations.

Final Thoughts on DFM and Product Quality

By integrating Design for Manufacturability into your product development process, you can significantly enhance product quality. The steps outlined above not only streamline manufacturing but also ensure that products meet customer expectations and industry standards.