How Does Thermoplastic Injection Ensure Precision in Plastics?

Thermoplastic injection is a revolutionary process that caters to the manufacturing of precise plastic components. But how does it actually ensure such accuracy? In this blog, we'll explore the various facets of thermoplastic injection and how they contribute to making high-quality products.

Understanding Thermoplastic Injection

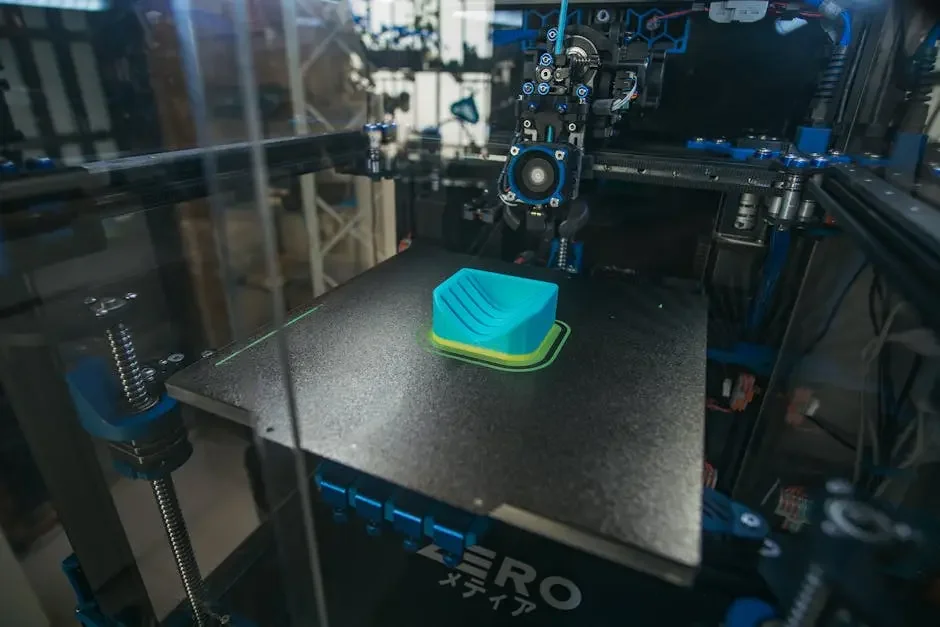

Thermoplastic injection is a manufacturing process that involves melting thermoplastic materials and injecting them into molds. This allows for the creation of detailed and precise parts, crucial in industries ranging from automotive to consumer products.

Through this method, manufacturers can achieve complex geometries that are often unfeasible with traditional methods. Each molded part can be produced with exact specifications, emphasizing the technology's role in ensuring quality and consistency.

Moreover, the versatility of thermoplastics plays a significant role in the process. These materials can be reshaped multiple times without degrading, allowing for various applications and minimizing waste.

The Role of Molds in Precision

Molds are a vital component of the thermoplastic injection process. The precision of the mold design directly influences the accuracy of the final product, ensuring that each piece fits together seamlessly.

A well-engineered mold can capture even the finest details of a design, which is indispensable for intricate parts. This necessity makes mold design both an art and a science, requiring engineers to collaborate closely with designers.

Furthermore, multi-cavity molds can enhance productivity, allowing simultaneous production of several identical parts. This not only boosts efficiency but also reinforces precision across all produced units.

Temperature Control and Its Impact

Maintaining an optimal temperature during the injection process is essential. Properly controlled temperatures ensure that the thermoplastic flows smoothly into the mold, minimizing defects and enhancing dimensional accuracy.

Variations in temperature can significantly affect the viscosity of the molten plastic, which in turn determines how well it fills the mold. If the temperature is too low, the material may not achieve the necessary flow rates; too high, and it can degrade.

Temperature sensors and control systems must, therefore, be employed diligently to monitor and adjust conditions in real-time, ensuring a consistently high-quality output across multiple production runs.

Importance of Pressure in Injection

Applying the right pressure when injecting thermoplastics is crucial for achieving precision. Increased pressure can help fill intricate mold designs and ensure uniformity in the final product, reducing the likelihood of air pockets or inconsistencies.

This pressure control also affects cycle time; higher pressures can often lead to faster filling and cooling times, further improving the overall efficiency of the production process.

Maintaining an adequate balance—too much pressure can lead to defects such as warping—requires experienced operators who understand the dynamics of the materials involved.

Advantages of Thermoplastic Injection

This method offers numerous advantages including high production rates, reduced waste, and the ability to manipulate material properties. All of these factors contribute to achieving precision in plastic components and maintaining quality standards.

Another compelling benefit is cost-effectiveness: high-volume production through thermoplastic injection minimizes the per-unit cost, making it economically viable for manufacturers. This value is particularly appealing in competitive markets.

In addition, the ability to recycle thermoplastics adds an eco-friendly aspect to the process, aligning with industries’ increasing focus on sustainability. As such, manufacturers can achieve precision while minimizing their environmental footprint.

Wrapping Up the Precision Journey

In summary, thermoplastic injection is a game-changer in the plastics industry, providing unparalleled precision and efficiency. By understanding its key steps and processes, manufacturers can significantly enhance the quality of their products.