What Makes Precision Plastic Machining a Cost-Effective Choice?

Precision plastic machining stands out in modern manufacturing for its efficiency and effectiveness. This blog will explore the key factors that contribute to its cost-effectiveness, making it a popular choice for businesses seeking quality and affordability.

Understanding Precision Plastic Machining

To appreciate the cost-effectiveness of precision plastic machining, it's essential to understand what it entails. This process utilizes high-precision tools to create parts from plastic materials with exceptional accuracy.

Precision plastic machining is not just about creating parts; it's about creating them right the first time. By employing advanced techniques and machinery, manufacturers can craft components that meet strict tolerances without the need for extensive modification.

Additionally, the ability to produce intricate designs sets precision plastic machining apart from other manufacturing methods. This capability not only allows for complex geometries but also reduces the need for additional processes, which can drive up costs overall.

Low Material Waste

One significant advantage of precision plastic machining is that it minimizes material waste. The process is designed to use just the right amount of plastic needed for each part, reducing excess costs.

In traditional manufacturing methods, excess material can lead to increased costs and environmental waste. In contrast, precision plastic machining focuses on efficiency by optimizing the cutting paths and tool paths, ensuring that less scrap material is produced.

As a result, businesses benefit from lower raw material costs while simultaneously contributing to sustainability efforts. This advantageous combination is becoming increasingly appealing in an eco-conscious market.

Enhanced Production Speed

Precision plastic machining allows for rapid production, enabling manufacturers to meet tight deadlines and customer demands more efficiently, ultimately leading to lower labor costs.

By streamlining the production process, companies can reduce lead times dramatically. This efficiency translates to more products delivered to market faster, which can be a game-changer in competitive industries.

Moreover, the accelerated pace of production can also enhance cash flow. When products move quickly through the manufacturing pipeline, businesses can reinvest and innovate without facing the bottlenecks that often plague traditional methods.

Versatility in Design and Materials

Another cost-effective aspect of this machining is its ability to work with various plastic materials and designs. This versatility allows businesses to explore innovative solutions without significant investment in new tooling.

For manufacturers, having the flexibility to switch between materials means they can adapt to trends or customer needs without incurring hefty costs. By optimizing their resource utilization, they can deliver tailor-made solutions effectively.

Furthermore, the scope for design variations enhances creativity in product development. Companies can produce prototypes rapidly, aiding in the iterative design process that is so vital in today's fast-paced market.

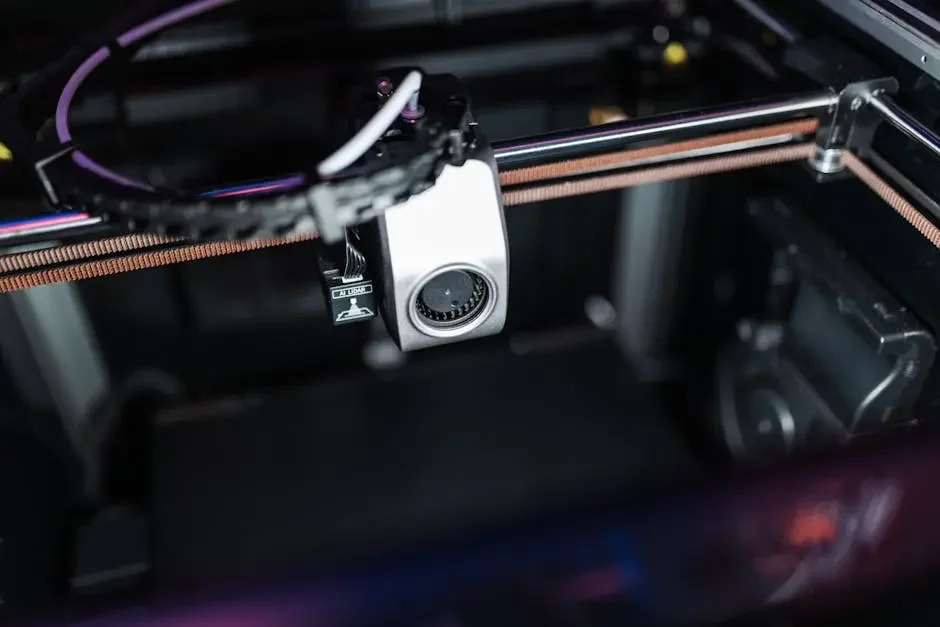

Utilizing Advanced Technology

The use of state-of-the-art machinery in precision plastic machining leads to improved quality control and reduced errors, further enhancing cost-effectiveness by decreasing rework and scrap rates.

Investing in advanced technology means that manufacturers can produce parts that not only meet but exceed quality standards. This reliability fosters trust with customers, leading to repeat business—a key contributor to long-term cost-effectiveness.

Additionally, with ongoing advancements in machining technology—including automation and AI integration—the potential for further cost reductions and efficiency improvements is significant. This promise of continual improvement makes precision plastic machining a sound financial choice for manufacturers of all sizes.

Key Takeaways

In summary, precision plastic machining offers a combination of efficiency, reduced waste, versatility, and advanced technology that makes it a smart investment for manufacturers. By understanding these factors, businesses can make informed choices that maximize their operational efficiency and minimize costs.