How Can Tooling Expertise Optimize Injection Molding Processes?

Injection molding is a crucial process in the manufacturing industry, and optimizing it can lead to significant improvements in efficiency and product quality. Tooling expertise plays a vital role in this optimization. In this blog, we will explore how a deep understanding of tooling can enhance injection molding processes step by step.

Understand the Role of Tooling in Injection Molding

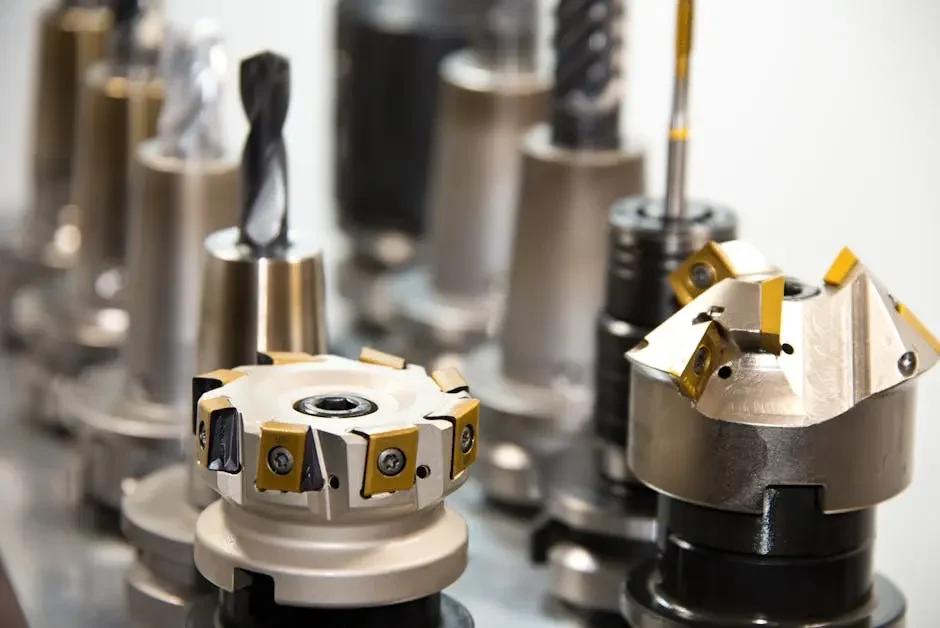

Tooling is fundamental to injection molding as it shapes the final product. Learning about different types of molds and their functions is the first step in improving processes.

Notably, the type of tooling used can greatly influence production efficiency. Experts emphasize a variety of molding methods, from single-cavity molds to multi-cavity molds, each serving unique purposes.

Moreover, understanding how tools affect materials can lead to more effective molding practices. For instance, different plastics require specific mold designs, impacting the thermal dynamics during processing.

By engaging with tooling engineers, manufacturers can gain insights that lead to enhanced mold designs. This collaboration can unveil opportunities for maximizing both speed and quality.

Evaluate Current Tooling Techniques

Assess existing tooling practices to identify areas for improvement. This evaluation helps in pinpointing inefficiencies and potential enhancements in the molding process.

Conducting a comprehensive audit of tooling practices enables businesses to recognize gaps. For example, outdated molds might lead to higher reject rates, wasting materials and time.

In particular, gathering feedback from operators can uncover real-world performance issues that might not be visible in theoretical assessments. Their hands-on experience is invaluable.

Once you’ve identified inefficiencies, prioritize upgrades that will yield the highest return on investment. A well-planned approach can revolutionize your production outcomes.

Incorporate Advanced Technology

Utilizing modern technology in tooling, such as CAD and simulation software, allows for precise mold designs and predicts potential issues before production.

Advanced tooling techniques like 3D printing also open new doors for rapid prototyping. This reduces lead times significantly and allows for more agile responses to market demands.

Moreover, simulation technology can assist in visually identifying flow patterns of materials within molds. This capability helps in developing more efficient tooling layouts.

By integrating industry 4.0 technologies, manufacturers can monitor mold performance and make adjustments in real-time, thus optimizing production efficiency.

Invest in Training and Development

Ensure that staff are well-trained in the latest tooling techniques. Continuous education helps to adapt to new trends and technologies in injection molding.

Training programs tailored to specific tooling challenges can foster a culture of learning. Regular workshops encourage employees to share knowledge and solve problems collaboratively.

Additionally, using mentorship either through external trainers or seasoned internal staff can significantly enhance the skill set of your workforce, leading to fewer mistakes and greater innovation.

A commitment to development boosts morale and fosters loyalty, ensuring that your team is invested in the success of the tooling process and the company as a whole.

Monitor and Adjust for Continuous Improvement

Regularly review the molding process and make necessary adjustments. Continuous monitoring helps in maintaining high standards and identifies new areas for optimization.

Establish a system for tracking performance metrics, such as cycle times and defect rates. Analyzing this data over time can uncover trends that necessitate proactive changes in tooling.

Moreover, soliciting continuous feedback from the production floor keeps everyone aligned and engaged in the optimization process. Everyone's input can generate fresh ideas for improvement.

Furthermore, not only should you react to failures but also recognize successful practices. Share these wins with the team to inspire ongoing refinement efforts.

Wrapping Up

With the right tooling expertise, manufacturers can achieve a streamlined injection molding process that not only reduces costs but also enhances product quality. By investing in skilled professionals and advanced techniques, businesses can remain competitive and meet market demands effectively.