The Future of Custom Plastic Solutions in Modern Manufacturing

As manufacturing continues to evolve, the demand for innovative and adaptable materials has never been greater. Custom plastic solutions are at the forefront of this transformation, offering unrivaled flexibility and functionality. In this blog, we’ll explore how these bespoke solutions are shaping the future of industries and enhancing production processes.

The Rise of Custom Plastic Solutions

Custom plastic solutions have gained prominence in various industries due to their adaptability and performance. We'll look into the factors driving this rise, including technological advancements and the need for specialized products.

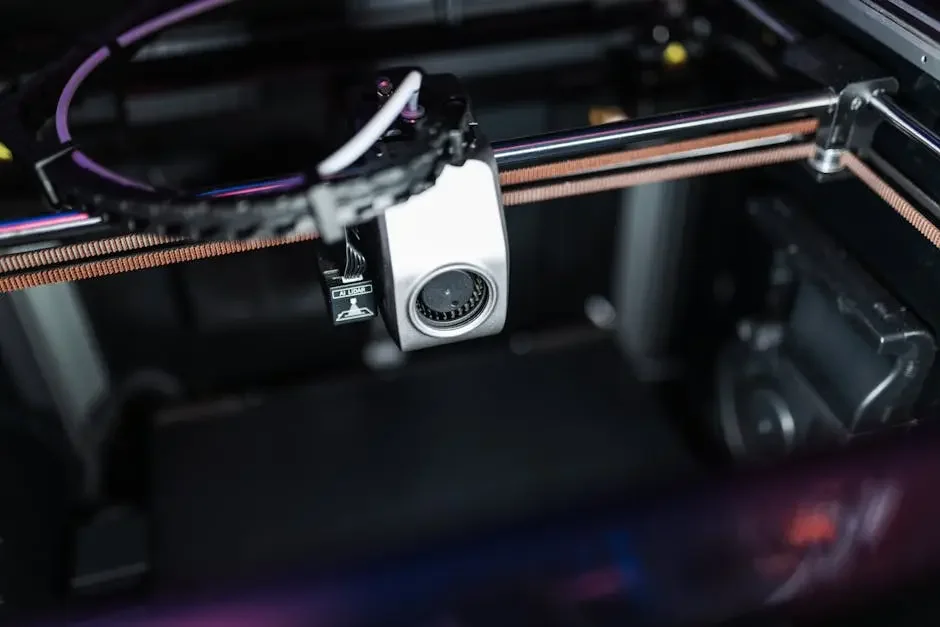

One of the primary drivers behind the surge of custom plastics is their integration with cutting-edge technology. With the advent of 3D printing and advanced manufacturing techniques, companies can now produce intricate designs that were once unimaginable. This shift not only allows for customization but also significantly reduces waste—an important consideration in our environmentally-conscious world.

Moreover, the increased demand for personalized products has pushed manufacturers to explore these solutions further. Industries ranging from consumer goods to electronics are recognizing that custom plastics can be tailored to specific needs, enhancing both functionality and aesthetic appeal. As a result, businesses that invest in custom plastic solutions are often able to capture niche markets and boost their competitive edge.

Advantages of Custom Plastics Over Traditional Materials

Custom plastics offer numerous advantages when compared to traditional materials like metal or glass. In this section, we will discuss their lightweight nature, cost-effectiveness, and the ability to be molded into complex shapes.

The lightweight nature of custom plastics is one of their standout features. In industries such as automotive and aerospace, reducing weight translates directly into improved fuel efficiency and overall performance. Unlike heavier materials, plastics enable manufacturers to create products that are easy to handle and transport, ultimately leading to lower shipping costs and faster delivery times.

Cost-effectiveness is another significant advantage. While the initial investment in custom tooling may seem daunting, the long-term savings are substantial. Custom plastics can be produced in larger quantities more efficiently, leading to reduced per-unit costs. Additionally, the lower energy requirements for processing and manufacturing further enhance their economic appeal.

Finally, the versatility of custom plastics cannot be overstated. Unlike traditional materials, they can be molded into intricate designs that meet specific requirements without compromising structural integrity. Whether it’s for delicate medical devices or robust industrial components, custom plastics can be engineered to meet the unique challenges of each application.

Applications in Various Industries

From automotive to healthcare, custom plastic solutions are revolutionizing production processes across various sectors. We'll explore specific applications and case studies that highlight their versatility.

In the automotive industry, custom plastics are redefining vehicle design. Interior components that were once made from metal or wood are now crafted using lightweight custom plastics, reducing overall vehicle weight and improving comfort. Companies like Tesla exemplify this shift, employing custom molded plastics for aesthetic and functional parts, such as dashboards and panels.

Healthcare is another field where custom plastic solutions shine. Medical devices, including syringes and prosthetics, benefit from the precision and customization that these materials offer. By using biocompatible plastics, manufacturers ensure not only performance but also patient safety. This has led to the rapid development of tailored solutions that meet specific medical needs, improving outcomes for patients around the world.

Moreover, the packaging industry is seeing a remarkable transformation thanks to custom plastics. With an increasing focus on sustainability, manufacturers are turning to custom solutions that not only protect products effectively but also minimize environmental impact. Biodegradable plastics, designed specifically for packaging, illustrate how innovation in custom materials is directly addressing global environmental concerns.

The Role of Sustainable Practices

Sustainability is a significant factor in modern manufacturing. This section will delve into how custom plastic solutions can be designed with eco-friendly practices in mind, contributing to a greener future.

As the pressure to adopt sustainable practices intensifies, custom plastic manufacturers are stepping up to the challenge. Innovations such as recycled plastics and bio-based materials are just a few examples of how this sector is evolving to meet eco-conscious demands. By utilizing waste plastics in their production processes, manufacturers save resources and reduce pollution, leading to a more sustainable manufacturing model.

Furthermore, custom plastics can be designed for recyclability. This ensures that at the end of their life cycle, these products can be reprocessed into new products, creating a circular economy. Manufacturers adopting this approach are not just complying with regulations; they are positioning themselves as leaders in an increasingly eco-conscious market.

Future Trends in Custom Plastic Manufacturing

What does the future hold for custom plastic solutions in manufacturing? We’ll look at emerging technologies, materials, and practices that are set to redefine the landscape of custom plastics.

One of the most exciting trends is the integration of artificial intelligence and automation into the manufacturing process. By employing AI-driven analytics, companies can identify trends, predict customer preferences, and optimize production schedules. This technology not only enhances efficiency but also allows for finer customization in product development, paving the way for highly specialized solutions.

Another emerging trend is the focus on smart materials. These are plastics that can change their properties in response to environmental stimuli, such as temperature or moisture. This innovation could lead to products that adapt in real-time, offering enhanced functionality and value. Imagine a packaging solution that can change its composition based on temperature, ensuring the contents remain optimal for longer.

As we look ahead, the collaboration between different sectors will be crucial. The convergence of technology, sustainability, and creative design will drive the next wave of innovation in custom plastic solutions. With cross-industry partnerships, manufacturers can share knowledge and resources, resulting in more groundbreaking products and solutions that meet the demands of an ever-changing marketplace.

Embracing the Future of Custom Plastic Solutions

In conclusion, the future of custom plastic solutions in modern manufacturing is bright. As technology advances and industries seek more efficient and sustainable options, these tailored materials will continue to play a pivotal role. Embracing innovation in custom plastic solutions not only enhances product quality but also positions manufacturers for success in a competitive landscape.