The Art of Mold Design in Precision Plastic Manufacturing

Mold design is a crucial part of precision plastic manufacturing, where creativity meets engineering. In this blog, we'll explore the intricacies of mold design, its importance, and the impact it has on the manufacturing process. Whether you're a seasoned professional or new to the field, understanding the art of mold design can enhance the quality of your products and streamline your production.

Understanding the Basics of Mold Design

Mold design starts with understanding the basic principles that dictate how molds function. This section will cover the fundamental concepts, such as the different types of molds, materials used, and the initial design considerations that go into creating effective molds.

At its core, mold design is about creating a cavity that will give shape to molten plastic. There are several molds, including injection molds, compression molds, and blow molds, each suited for specific applications and materials. Understanding the purpose of each type is essential for a successful outcome. For instance, injection molds are ideal for producing intricate designs with high precision, while blow molds are often used for hollow objects.

Beyond just the type of mold, you must also consider the materials used in the mold itself. Steel and aluminum are common choices, each offering unique advantages and considerations. Steel molds, while more durable, are also heavier and more expensive, whereas aluminum molds can be cost-effective for short production runs but may not withstand the rigors of long-term use. The decision often hinges on factors like production volume, timeline, and budget.

Lastly, initial design considerations cannot be overlooked. The dimensions, cooling channels, and even draft angles play crucial roles in achieving a successful mold design. Consideration of these factors early on in the design process can save time and resources, allowing for smoother production workflows. So, whether you’re diving into your first project or have years of experience under your belt, mastering these basics lays the foundation for more complex mold design challenges you'll encounter.

The Role of CAD Software in Mold Design

Computer-Aided Design (CAD) software has revolutionized mold design. This section will discuss the advantages of using CAD, including improved precision, better visualization, and the ability to make complex designs quickly. We'll also touch on some popular CAD tools used in the industry.

CAD software enables designers to create detailed digital representations of mold designs, enhancing both accuracy and efficiency. Unlike traditional drawing methods, CAD allows for quick modifications, making it easier to refine and improve designs without starting from scratch. This versatility not only saves time but also enables designers to visualize their work in 3D. Immersing yourself in this digital environment provides an unparalleled view of how components fit together, revealing potential issues before physical production begins.

One of the standout features of CAD is its ability to simulate manufacturing processes. This can include the flow of molten plastic or the cooling phases of a mold cycle. By simulating different scenarios, designers can identify potential bottlenecks or weaknesses in the mold. This proactive approach minimizes errors and helps optimize design before it even reaches the production floor. Ultimately, this translates into cost savings and improved turnaround times.

There are several CAD tools used for mold design, such as SolidWorks, AutoCAD, and CATIA, each catering to different needs and levels of complexity. For example, SolidWorks is popular for its user-friendly interface and robust functionality, making it ideal for those just starting in mold design. CATIA, on the other hand, is favored in industries requiring extensive collaboration and sophisticated design features. Understanding the strengths and weaknesses of each tool can empower designers to choose the best software for their project needs.

The Importance of Material Selection

Choosing the right materials for molds is vital to ensure product quality and durability. In this section, we'll explore various materials used for mold making, discussing their properties, advantages, and how they affect the final product.

Material selection is perhaps one of the most critical decisions a mold designer faces. The right material not only influences the mold's longevity but also impacts the manufacturing process itself. Common materials include steel, aluminum, and various composites. Steel, often preferred for its robustness, excels in long-term applications, but it comes at a higher cost. Conversely, aluminum is lighter and more cost-effective, making it suitable for short production runs or prototyping, but may not withstand extensive use.

Beyond the initial cost, other factors like thermal conductivity also play a significant role in material choice. High thermal conductivity materials can help manage cooling times, enhancing production efficiency. For instance, beryllium copper combines excellent thermal properties with good strength, making it a popular choice for complex molds where heat transfer is crucial. Understanding the thermal properties of different materials can lead to smarter design choices that optimize production workflows.

It's also essential to consider the type of plastic being molded. Different plastics adhere to molds differently, which can impact the choice of material. For example, materials that are overly porous may trap plastic and lead to defects in the final product. By carefully selecting the right materials, manufacturers can reduce waste, streamline production, and deliver higher quality outcomes.

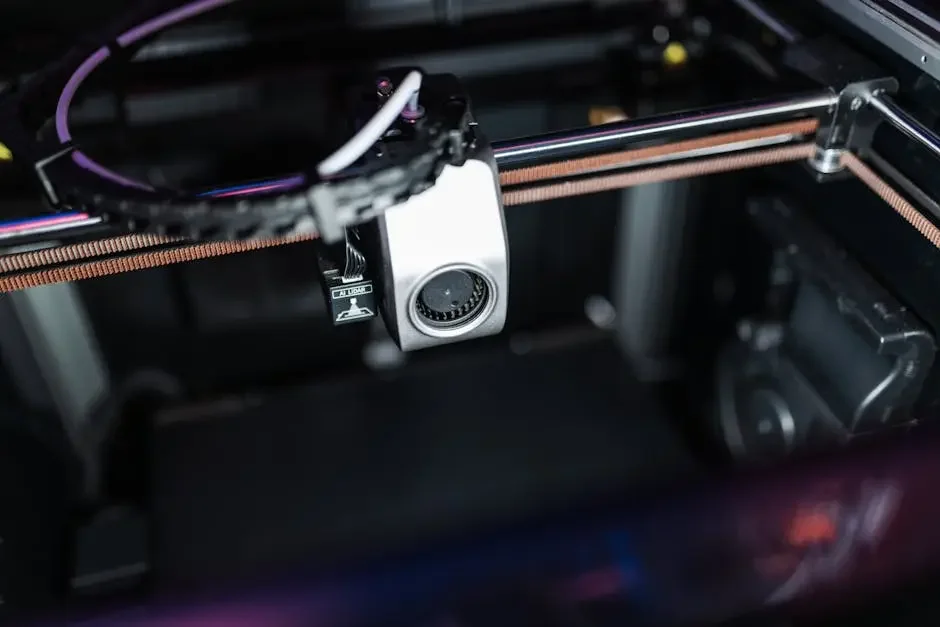

Incorporating Advanced Technologies

As technology evolves, so does mold design. This section will highlight some advanced techniques and technologies, such as 3D printing and injection molding innovations, that are shaping the future of mold design in the plastic manufacturing industry.

3D printing is one of the most disruptive technologies impacting mold design today. The ability to produce prototypes quickly means designers can iterate faster than ever before. This rapid prototyping facilitates testing and allows for real-time adjustments based on observed performance. Moreover, 3D printing can create intricate geometries that traditional methods may struggle with, further expanding the possibilities in mold design.

In addition to 3D printing, advancements in injection molding technology have also transformed the industry. Techniques such as multi-material injection molding allow for the production of complex parts with varied properties in a single mold. This not only reduces manufacturing time but also opens the door to entirely new product designs, enhancing functionality without sacrificing aesthetics. Staying informed about these advancements can offer a competitive edge in a rapidly evolving landscape.

Lastly, automation and smart technology integration are beginning to play their part in mold design. Automated systems can monitor mold performance in real-time, alerting designers and engineers to issues in the manufacturing process. This proactive approach not only helps in maintaining high product quality but can also lead to cost savings in maintenance and operations. Embracing such technologies will be key for mold designers looking to thrive in the future.

Testing and Quality Assurance in Mold Design

Once a mold is designed, testing and quality assurance become critical to ensure reliability and performance. This section will dive into the different testing methods used to evaluate mold effectiveness and the importance of rigorous quality control processes.

Testing begins long before a mold is ever put into production. It’s essential to evaluate the design under various conditions to identify potential points of failure. Common testing methods include flow analysis, thermal imaging, and pressure testing. Each of these methods serves to simulate the conditions the mold will experience during actual production, providing invaluable data that can influence design improvements.

In addition to initial testing, ongoing quality assurance during the production process is vital. Regular inspections can help detect issues before they escalate, ensuring that defects are caught early. Implementing a robust quality management system guides teams in maintaining consistent standards and reaching production goals. Transparency in this process also builds trust among stakeholders, reinforcing the importance of quality in mold design.

Furthermore, documentation plays a fundamental role in quality assurance. Each test, adjustment, and observation should be carefully recorded to create a comprehensive history of the mold. This documentation not only supports continuous improvement efforts but also provides invaluable insight for future projects. Ultimately, a commitment to quality and testing ensures that designers meet industry standards and customer expectations, fostering confidence in their products.

Common Challenges and Solutions in Mold Design

Every mold designer faces challenges. This section will examine common obstacles in the mold design process and provide practical solutions to overcome them, ensuring a smoother workflow and better end products.

One of the primary challenges in mold design is deformation during the cooling process. If the mold cools unevenly, it can lead to warping, ultimately affecting the quality of the final product. To combat this, designers can employ advanced cooling techniques, such as incorporating conformal cooling channels that better control temperature distribution. This not only minimizes warping but also enhances overall cycle times.

Another common hurdle is managing the balance between intricate design features and production efficiency. While complex designs can offer aesthetic and functional advantages, they may also complicate the manufacturing process. A good strategy is to iterate on simpler designs that can be produced more efficiently without sacrificing quality. By finding the sweet spot between complexity and practicality, manufacturers can optimize production without compromising on aesthetics.

Finally, communication between design and production teams is crucial. Often, disconnects between these groups can lead to misunderstandings about the feasibility of certain designs. Fostering an environment of collaboration ensures that everyone can contribute to the solution. Regular meetings and open channels of communication can bridge gaps, making it easier to share insights and tackle challenges together. This collaborative approach ultimately leads to improved product quality and a more efficient workflow.

Final Thoughts on Mold Design Mastery

In conclusion, the art of mold design is an essential aspect of precision plastic manufacturing that combines creativity, engineering skills, and practical knowledge. By mastering the principles of mold design, manufacturers can ensure high-quality products while optimizing efficiency and costs. As the industry continues to evolve, staying informed about the latest trends and technologies in mold design will be vital for success.