The Role of Part Design in Precision Plastic Production

In the world of manufacturing, particularly in precision plastic production, part design plays a crucial role. The intricate details of design not only affect the functionality of the final product but also influence production efficiency, cost, and waste reduction. In this blog, we'll explore how effective part design can lead to successful precision plastic production and delve into the various factors that come into play.

Understanding Part Design in Precision Plastic Production

Part design involves the creation and engineering of plastic components with precision in mind. This section will break down the basics of part design, its importance in the manufacturing process, and how it integrates with other elements of production.

At its core, part design is the blueprint from which all subsequent production processes unfold. From initial sketches to detailed CAD models, every step is vital. Understanding the nuances of what makes a design effective can be the difference between a project that succeeds and one that encounters serious challenges down the line.

Consider how a well-thought-out design can streamline the entire manufacturing journey. By taking into account the capabilities of the materials used, the expected conditions of use, and the manufacturing techniques available, designers can craft components that not only function well but also fit right into the production pipeline.

Key Principles of Effective Part Design

There are several core principles that drive successful part design, including simplicity, functionality, and manufacturability. We will explore these principles and how they can lead to stronger, more cost-effective products.

Simplicity is paramount. A design that is overly complicated can lead to confusion during production, increase the likelihood of errors, and ultimately inflate costs. By keeping designs straightforward and user-friendly, manufacturers can avoid a myriad of complications that arise from trying to implement complex assembly processes.

Functionality must also remain at the forefront of any designer's mind. A stunning design that fails to perform its intended role will inevitably disappoint users. Striking a balance between aesthetics and usability is essential. This is where collaboration between designers and engineers becomes pivotal.

Lastly, manufacturability should never be an afterthought. Successful designs need to take into consideration not just the visual and functional aspects, but also how easily they can be produced. By leveraging existing technologies and understanding material properties, designers can create parts that are not only innovative but also feasible to manufacture at scale.

The Impact of Design on Production Efficiency

The relationship between part design and production efficiency is undeniable. By optimizing designs, manufacturers can reduce production time, lower costs, and minimize waste. In this section, we'll look at specific examples where design choices led to significant improvements.

For instance, consider a scenario where a manufacturer shifted to a more modular design approach. By creating parts that were compatible with various assemblies, not only did they reduce the number of components needed, but they also sped up the assembly process. This adaptability translates to improved inventory management and reduced storage costs.

Additionally, an optimized design can simplify the manufacturing process, allowing for more automation. Automated systems can work more efficiently when parts have been designed with consistency and ease of handling in mind. This shift not only saves costs but also enhances production speed, resulting in quicker turnarounds for client orders.

Reducing Waste Through Smart Design Choices

Waste reduction is a critical factor in sustainable manufacturing. This section will highlight how thoughtful part design can minimize material waste and enhance sustainability in the production process.

Smart design choices, such as the use of design for manufacturing (DFM) principles, enable designers to evaluate and eliminate unnecessary material usage. Rather than simply focusing on aesthetics or performance metrics, DFM demands that manufacturing constraints be incorporated early on in the design process, thus reducing excess material and promoting efficient material usage.

By employing such practices, companies can take significant strides towards sustainability while also reducing costs. Waste isn’t just a financial burden; it has environmental implications as well. With every component designed for efficiency, businesses can minimize their footprint on our planet.

Collaboration in the Design Process

Effective part design doesn’t happen in isolation. Collaboration among designers, engineers, and manufacturers is key to creating optimal products. We’ll delve into how this teamwork can lead to innovative solutions in plastic production.

Involving a diverse range of expertise in the design process leads to more comprehensive solutions. Designers might envision a product from a user's perspective, while engineers can offer insights on feasibility and manufacturing techniques. When these perspectives align, the final design can become truly groundbreaking.

Moreover, the collaboration doesn’t end once the design is finalized. Continuous feedback loops during production help identify any challenges early, allowing teams to make necessary adjustments. This ongoing dialogue ensures that part design evolves based on real-world performance and stakeholder feedback.

Future Trends in Part Design for Precision Plastic Production

As technology advances, so do the possibilities for part design. In this final section, we will discuss emerging trends and technologies that are shaping the future of precision plastic production.

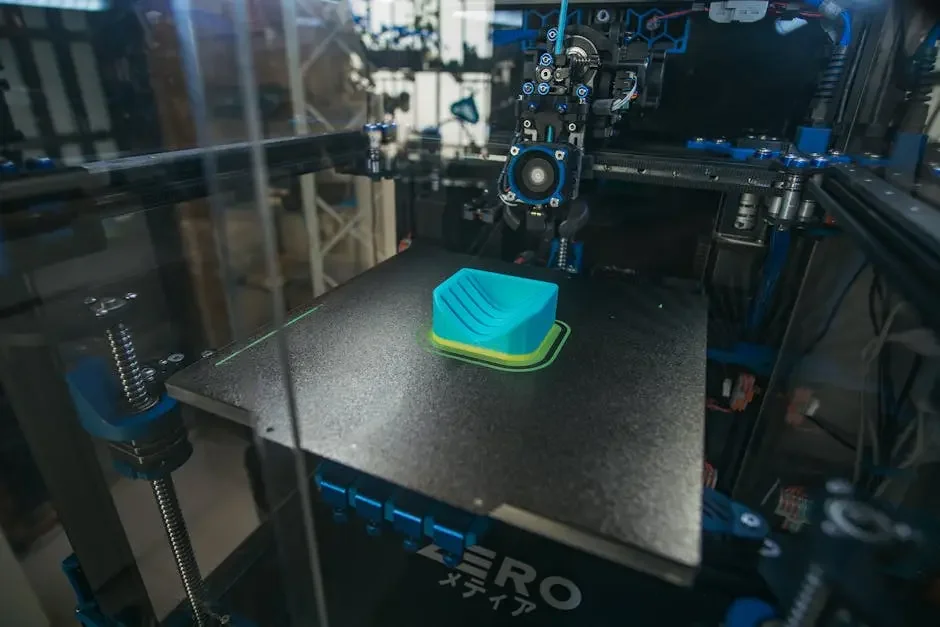

One significant trend is the integration of additive manufacturing into part design processes. 3D printing allows for innovative shapes and structures that were previously unfeasible with traditional methods. Designers are now rethinking what’s possible, leading to lighter, stronger parts that save material without compromising performance.

Furthermore, the incorporation of digital twin technology is revolutionizing how designers can simulate and test their ideas. By creating virtual replicas, designers get immediate feedback, enabling them to iterate quickly and get closer to an optimal design before entering the physical production stage.

Final Thoughts on Part Design's Impact

Understanding the significance of part design in precision plastic production is essential for anyone involved in manufacturing. By focusing on design elements that enhance efficiency and reduce costs, businesses can ensure their success in a competitive market. As we continue to innovate and push the boundaries of what's possible with plastic production, thoughtful part design will remain at the forefront.